Product Description:

When it comes to high-quality Alloy Steel Tube products, look no further than our Alloy Steel Line Pipe. This product is designed to meet the demanding requirements of various industries, offering exceptional performance and durability.

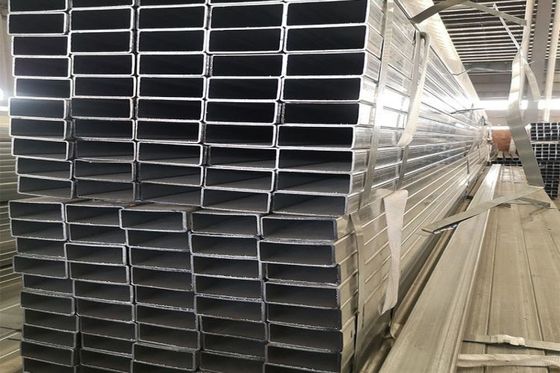

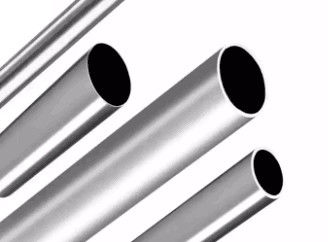

The Alloy Steel Tube is known for its bright and shiny appearance, making it a visually appealing choice for a wide range of applications. Its striking appearance not only adds a touch of elegance to any project but also reflects the high-quality craftsmanship and attention to detail that goes into its production.

One of the key advantages of the Alloy Steel Tube is its strong corrosion-proof properties. This makes it an ideal choice for applications in industries such as oil, gas, and fertilizer, where exposure to harsh environments and corrosive substances is common. The Alloy Steel Tube's resistance to corrosion ensures that it maintains its integrity and performance even in challenging conditions, prolonging its lifespan and reducing maintenance costs.

In addition to its corrosion-proof properties, the Alloy Steel Tube is also well-suited for a variety of applications. Whether it's used as an Alloy Steel Line Pipe, Alloy Steel Heat Exchanger Tube, or Alloy Steel Line Pipe, this versatile product delivers reliable performance and consistent results.

Furthermore, the Alloy Steel Tube is available with different end options to suit specific project requirements. Whether you prefer plain ends for a clean and seamless finish or beveled ends for enhanced weldability and strength, the Alloy Steel Tube can be customized to meet your needs.

For easy identification and traceability, the Alloy Steel Tube can be marked as required. This ensures that each piece is clearly labeled with relevant information, helping to streamline the installation and maintenance process.

In conclusion, the Alloy Steel Tube is a top choice for industries that demand high-performance, durable, and corrosion-resistant products. Its bright and shiny appearance, versatile applications, customizable end options, and easy identification make it a reliable and efficient solution for a wide range of projects. Trust in the Alloy Steel Tube to deliver exceptional performance and longevity, ensuring that your projects are built to last.

Features:

- Product Name: Alloy Steel Tube System

- Ends: Plain, Beveled, Threaded

- Width: 20mm-1800mm

- Advantage: Strong Corrosion-proof

- Production: Cold Drawn

- Edge: Mill Edge Slit Edge

Technical Parameters:

| Technical Parameter |

Description |

| Third Party Inspection |

BV, SGS, ASP |

| Technique |

Hot Rolled, Cold Drawn |

| Surface |

Anodized, Brushed, Mill Finished, Polished |

| Length |

Customized |

| Application |

Oil/Gas/Fertilizer |

| Ends |

Plain, Beveled, Threaded |

| Production |

Cold Drawn |

| Width |

20mm-1800mm |

| Advantage |

Strong Corrosion-proof |

| End |

Plain Ends / Beveled Ends |

Applications:

Alloy Steel Tube by JOHO, originating from China, is a premium product with ISO 9001 certification. This high-quality tube is ideal for a variety of applications across different industries due to its exceptional attributes.

The Alloy Steel Tube is versatile and can be used in various product application occasions and scenarios. One primary application is in the construction industry, where the tube is utilized in structural frameworks, providing strength and durability. The Alloy Steel Tube is also suitable for use in the automotive sector, particularly in the manufacturing of vehicle components.

Moreover, the Alloy Steel Tubular System is well-suited for industrial machinery, offering reliable performance under high-pressure conditions. Its resilience makes it a preferred choice for hydraulic systems and pneumatic applications. The tube's ability to withstand extreme pressure and temperature variations makes it an integral component in the production of hydraulic cylinders and industrial boilers.

Additionally, the Alloy Steel Pressure Tube is commonly used in the oil and gas sector for drilling operations and pipeline construction. Its corrosion-resistant properties ensure longevity in harsh environments, making it a dependable choice for offshore projects.

With a minimum order quantity of 1 ton, customers can benefit from the packaging details that include woodencase or woven bag options. The delivery time of within 40 days ensures timely availability of the product, meeting project deadlines efficiently. Payment terms such as LC, TT, etc., offer flexibility to buyers, facilitating seamless transactions.

The Alloy Steel Tube is produced using cold drawn techniques, ensuring precision and consistency in dimensions. With a width range of 20mm to 1800mm and customizable lengths, customers can tailor the product to their specific requirements. The bright and shiny color of the tube enhances its aesthetic appeal, making it suitable for visible applications.

Furthermore, the Alloy Steel Tube is available with different end types, including plain, beveled, and threaded, catering to diverse installation needs. Whether for structural support, pressure systems, or industrial machinery, the Alloy Steel Tube by JOHO is a reliable choice for various product application occasions and scenarios.

Customization:

Product Customization Services for Alloy Steel Tube:

- Brand Name: JOHO

- Place of Origin: CHINA

- Certification: ISO 9001

- Minimum Order Quantity: 1 TON

- Packaging Details: Woodencase/Woven bag

- Delivery Time: within 40 days

- Payment Terms: LC,TT,ect,.

- Surface: Anodized, Brushed, Mill Finished, Polished

- Marking: As Required

- End: Plain Ends / Beveled Ends

- Application: Oil/Gas/Fertilizer

- Edge: Mill Edge Slit Edge

For Alloy Steel Line Pipe, Alloy Steel Heat Exchanger Tube, Alloy Steel Seamless Tube.

Support and Services:

Our Product Technical Support and Services for Alloy Steel Tube include:

- Expert guidance on material selection and compatibility

- Assistance with product specifications and dimensions

- Troubleshooting support for any issues related to the alloy steel tube

- Recommendations on proper handling, installation, and maintenance

- Access to resources such as technical documentation and product manuals

Packing and Shipping:

Product Packaging:

The Alloy Steel Tube is carefully packaged in durable cardboard boxes to ensure protection during transit. Each tube is securely wrapped in protective material to prevent scratches and damage.

Shipping:

Orders are typically shipped within 1-2 business days after payment confirmation. We use reputable shipping carriers to deliver the Alloy Steel Tubes to your doorstep quickly and safely. You will receive a tracking number to monitor the delivery status of your order.

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!  Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!