Product Description:

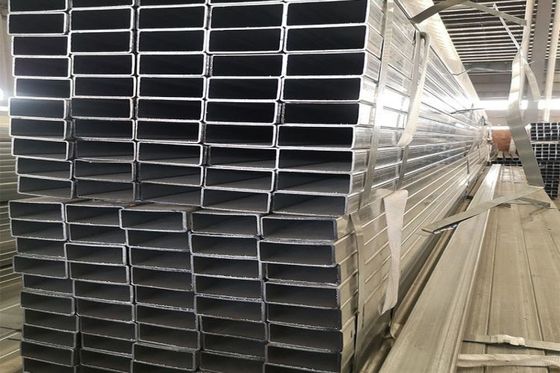

The Alloy Steel Tube is an essential component of the Alloy Steel Tubular System, used in various applications such as the manufacturing of Alloy Steel Boiler Tubes and Alloy Steel Pipes. This product is designed to meet the highest industry standards and is subjected to Third Party Inspections by reputable agencies such as BV, SGS, and ASP to ensure quality and compliance.

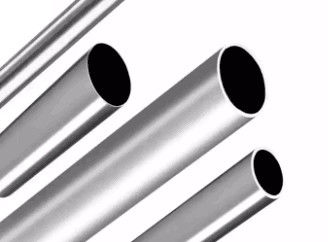

One of the key advantages of the Alloy Steel Tube is its exceptional strength and corrosion-proof properties. This makes it ideal for use in demanding environments where resistance to corrosion is crucial for long-term performance and durability.

The Alloy Steel Tube is available with customizable markings to meet specific project requirements. Whether it's identification codes, logos, or other markings, they can be applied as per the customer's needs.

When it comes to the edges of the Alloy Steel Tube, customers have the option to choose between Mill Edge or Slit Edge based on their preferences and application requirements. The Mill Edge provides a clean and uniform edge finish, while the Slit Edge offers flexibility in welding and other processes.

For the ends of the Alloy Steel Tube, customers can select from Plain, Beveled, or Threaded ends based on the installation and connectivity needs. The Plain end is suitable for standard applications, while the Beveled end facilitates welding processes by creating a sloped surface. The Threaded end allows for easy connection with other components using threaded fittings.

Features:

- Product Name: Alloy Steel Tube

- Ends: Plain, Beveled, Threaded

- Application: Oil/Gas/Fertilizer

- Third Party Inspection: BV,SGS,ASP

- Color: Bright, Shinny

- Production: Cold Drawn

Technical Parameters:

| Application |

Oil/Gas/Fertilizer |

| Color |

Bright, shiny |

| Production |

Cold Drawn |

| Technique |

Hot Rolled, Cold Drawn |

| Third Party Inspection |

BV, SGS, ASP |

| Ends |

Plain, Beveled, Threaded |

| Advantage |

Strong Corrosion-proof |

| Width |

20mm-1800mm |

| Surface |

Anodized, Brushed, Mill Finished, Polished |

| Edge |

Mill Edge, Slit Edge |

Applications:

The JOHO Alloy Steel Tube is a versatile product suitable for a wide range of applications across various industries. With its exceptional quality and strong corrosion-proof advantage, this Alloy Steel Tubular System is ideal for use in demanding environments such as the oil, gas, and fertilizer industries.

Originating from CHINA and certified with ISO 9001, the JOHO Alloy Steel Tube is a reliable and high-quality product that meets international standards. The minimum order quantity of 1 TON makes it accessible for both small and large-scale projects.

Whether it's for constructing an Alloy Steel Cylinder for high-pressure applications or for transporting fluids through an Alloy Steel Pipe, this product delivers exceptional performance and durability. The cold-drawn production process ensures precision and consistency in dimensions, making it a preferred choice for critical operations.

With a variety of edge options including Mill Edge and Slit Edge, customers can choose the most suitable configuration for their specific requirements. The packaging details in woodencase or woven bag ensure safe transportation and delivery of the product.

Customers can expect a prompt delivery time of within 40 days, allowing for efficient project planning and execution. Flexible payment terms such as LC, TT, etc., provide convenience and ease of transaction for buyers.

Furthermore, the JOHO Alloy Steel Tube can be customized with markings as required, adding a personalized touch to the product. Its versatility and durability make it an essential component in various industrial processes, offering reliable performance and longevity.

Customization:

Product Customization Services for Alloy Steel Tube:

Brand Name: JOHO

Place of Origin: CHINA

Certification: ISO 9001

Minimum Order Quantity: 1 TON

Packaging Details: Woodencase/Woven bag

Delivery Time: within 40 days

Payment Terms: LC,TT,ect,.

Length: Customized

Colour: Bright,shinny

Width: 20mm-1800mm

Ends: Plain, Beveled, Threaded

End: Plain Ends / Beveled Ends

Keywords: Alloy Steel Pipe, Alloy Steel Tubular System, Alloy Steel Heat Exchanger Tube

Support and Services:

Our company provides comprehensive Product Technical Support and Services for Alloy Steel Tube products. Our team of expert engineers and technicians are available to assist with any technical inquiries, troubleshooting, or product-related issues that may arise. We offer installation guidance, maintenance tips, and repair services to ensure optimal performance and longevity of your Alloy Steel Tube products. Additionally, we provide training programs and resources to help customers maximize the efficiency and effectiveness of their Alloy Steel Tube applications.

Packing and Shipping:

This Alloy Steel Tube is carefully packaged to ensure its safe delivery to you. It is wrapped in protective material and placed in a sturdy cardboard box to prevent any damage during transit.

For shipping, we use reliable carriers to deliver your Alloy Steel Tube promptly and securely. You will receive a tracking number so you can monitor the status of your shipment.

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!  Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!